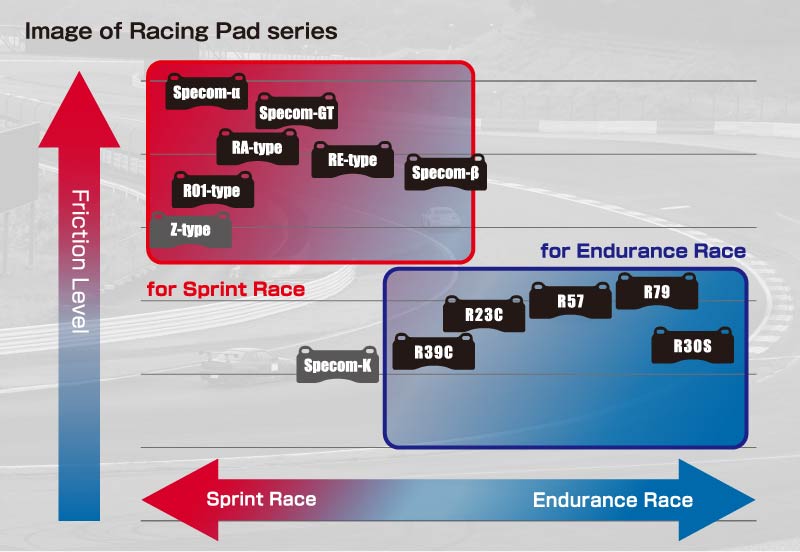

SPECIAL COMPOUND SERIES Made to order

More compounds available to meet the exacting needs of various cars/courses.

For FRONT PAD

R79C

Natural typeSpecifically formulated for GT3/GT4

- Improved initial bite from the former spec (R53C).

- Excellent life and stable friction over a wide range of temperatures.

- Superior control and modulation to minimize the ABS intervention.

| Friction Materials | Carbon Semi Metal |

|---|---|

| Initial Friction Level μ | 0.40 |

| Average Friction Level μ | 0.40~0.48 |

| Applications | SPRINT~5H |

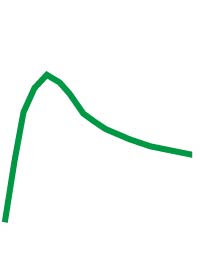

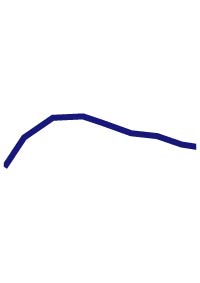

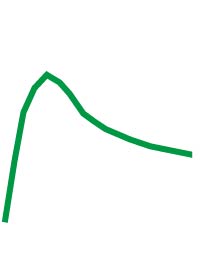

■μ Plot Shape

For race like

- GT3 Race Series

- Super GT(GT300)

- Super Taikyu

R57C

Flat typeFor heavier brake loads and longer distance

- Designed for tracks with heavy brake loads such as Motegi or Zhuhai.

- Stable friction level and firm pedals throughout endurance races.

| Friction Materials | Carbon Semi Metal |

|---|---|

| Initial Friction Level μ | 0.34 |

| Average Friction Level μ | 0.32〜0.40 |

| Applications | SPRINT~5H |

■μ Plot Shape

For race like

- GT3 Race Series

- Super GT(GT300)

- Super Taikyu

R23C

Natural typeA High level blend of Braking Power and Durability

- Balanced braking at high temperatures and high loads.

- Superior durability makes it ideal for medium to long distance races.

- More than two times more durable of the RA-type.

| Friction Materials | Carbon Semi Metal |

|---|---|

| Initial Friction Level μ | 0.38 |

| Average Friction Level μ | 0.30~0.35 |

| Applications | ENDURANCE |

■μ Plot Shape

For race like

- GT3 Race Series

- Super GT(GT300)

- Super Taikyu

- Endurance Races (4-7 hours)

R30S

Flat typeIncreased Braking Power and Better Durability

- Developed in Super Taikyu races.

- Superior stability with a long lasting firm pedal feel.

- Good compatibility with slotted discs; maintains high durability with an increase in brake power.

| Friction Materials | Sintered Metal |

|---|---|

| Initial Friction Level μ | 0.36 |

| Average Friction Level μ | 0.32~0.35 |

| Applications | ENDURANCE |

■μ Plot Shape

For race like

- GT3 Race Series

- Super GT(GT300)

- Super Taikyu(ST1/2/3/4 classes)

- Endurance Races (4-12 hours)

For FRONT PAD

R39C

Flat typeFormulated for GT3 Machines and other racing cars

- Stable performance under high temperatures and high loads

- Works well with latest racing ABS systems

| Friction Materials | Carbon Semi Metal |

|---|---|

| Initial Friction Level μ | 0.36 |

| Average Friction Level μ | 0.32~0.36 |

| Applications | SPRINT~ENDURANCE for REAR |

■μ Plot Shape

Test data showing the superior performance of the Specom series.

■ µ Plot Shape

This plot represents transition of friction level during a braking application.

High initial bite type gives drivers reliale braking performance at the initial braking application. Easy to decelerate with small pedal pressure even on the long straight line. Good for cars w/o brake servo.

Most common type in three types. Moderate braking force at the initial braking application. Easy to controll at the end of the braking application. Applicable for any car/circuit.

For users requiring great controllability. Least initial bite in three types. Flat friction level enables great controllability throughout the braking application. Most stable performance under continuous severe condition (continuous change of speed/temperature).

About Bedding-in

Competition-use brake pads need to go through a process to be pre-heated before a race to exhibit its full potential. This process is called bedding-in.

《 Method of bedding-in 》

When using new pads/discs for the first time on a circuit, start with 50% braking for about 5 minutes and then go back to the pit once and take at least 5minutes interval. After that, repeat 70~80% braking for about 10 minutes. Pit in again and take an interval of about 10 minutes. After that, gradually increase from 80% to 100% braking, and the bedding-in of pads/discs on circuit is completed.

《 Comparisons of the method of recommended bedding-in 》

| Low pressure | Medium to high pressure | High pressure | Cooling | |

| DIXCEL | 5 mins, then cooling of 5mins | 10mins, then cooling of 10mins | 80% to 100% pressure in 5mins | |

| Brand A | 150-80kph x 10 times (interval 600-800m) | 180-60kph x 5 times | cooling x 3 minutes | |

| Brand B | 50% braking x 5 minutes | 80-100% x 5 minutes | cooling x 2 minuites | |

| Brand C | 5 times | 5 times | 3 times | cooling x 20 minutes PARKING |

| Brand D | 3 sec braking x 30 times with LOW to HIGH pressure. 800m interval between each braking) | |||

| Brand E | 5times | 5 times at slow to medium speed (interval 500m) | ||

| Brand F | 145-40kph x 5 times | 2-3 laps | ||